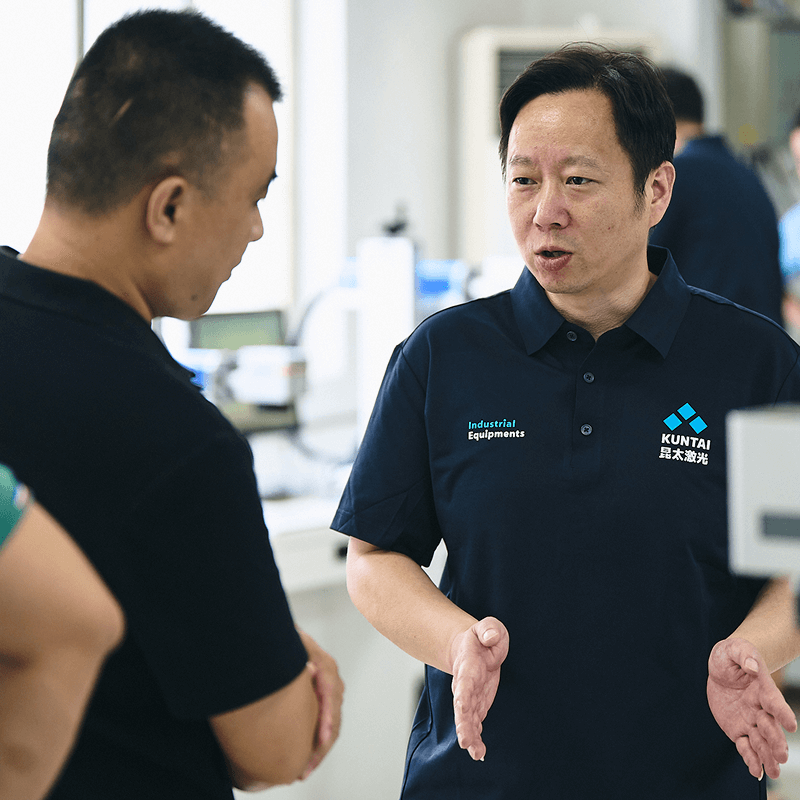

لحام الأجزاء الحساسة والغلاف الخارجي للإلكترونيات

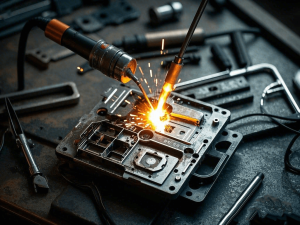

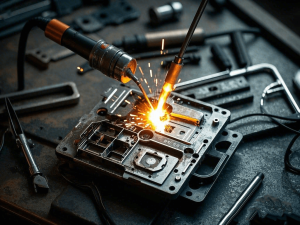

The electronics sector uses laser welding extensively to connect parts like circuit boards, batteries, and casings in devices such laptops

The electronics sector uses laser welding extensively to connect parts like circuit boards, batteries, and casings in devices such laptops

Different parts in the electronics sector need laser marking for a different use. Particularly with small and complex items, laser

The key reasons laser welding is chosen are its ability to generate high-quality, strong welds with low heat input, which

Laser marking is suitable for a wide range of everyday items Laser marking is based on the interaction between the

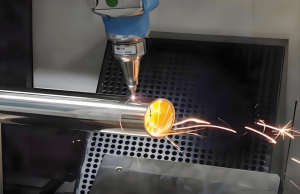

Why choose laser cutting? 1. Without specific tools, laser cutting can be applied on a great range of materials, therefore

Laser cleaning removes dirt, corrosion, oil, and paint by guiding highly intense laser beams at a surface. While leaving the

Laser cutting has several advantages in the building industry. It guarantees that, for structural integrity, components including beams and trusses

Laser cleaning is becoming more and more common in the building sector since it can safely remove stains like paint,

Laser marking is growing in popularity in the building industry especially for its accuracy, robustness, and flexibility. Its major application

Laser welding offers precise, rapid, adaptable solutions changing the construction. In structural steel building, it enables quick assembly of complex