Table of Contents

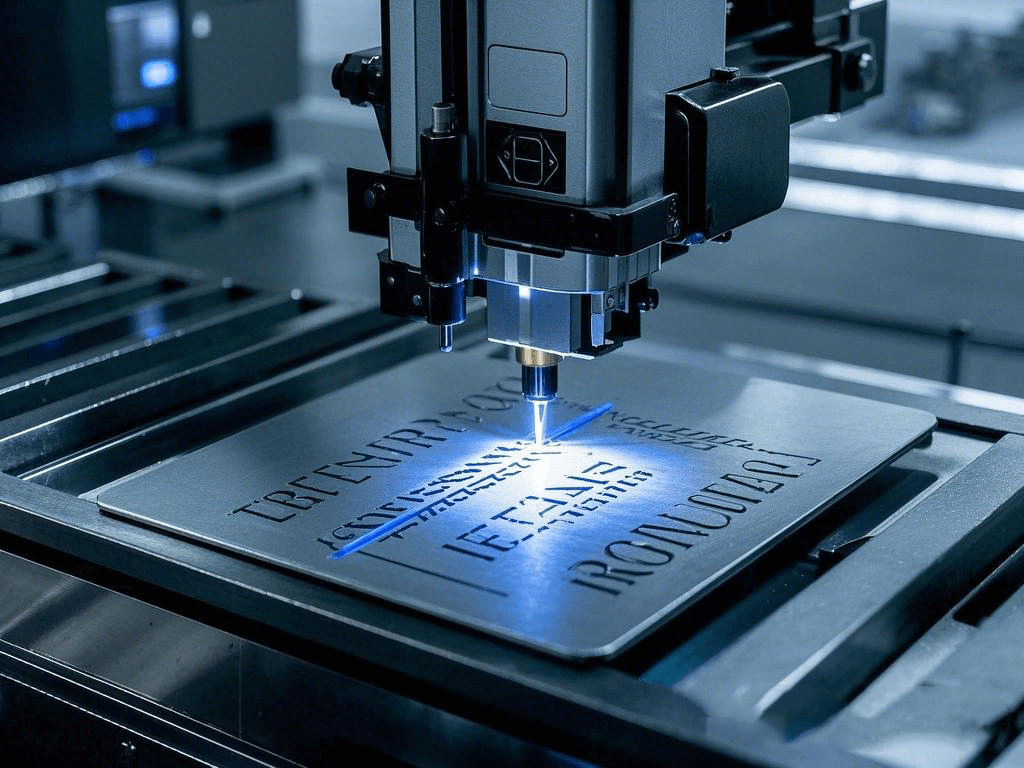

CO2 laser marking machines have reshaped how businesses build permanent and high-quality markings on different materials. They can precisely and quickly create markings for barcodes, logos, or intricate designs that are never possible with traditional methods.

These machines are broadly employed in different industries such as packaging, electronics, and automotive. In these industries, clear and long-lasting markings are vital for traceability, branding, and compliance.

The CO2 laser marking technology can handle a wide set of materials such as wood, leather, glass, and plastics. In our post today, we aim to deeply review CO2 laser marking machines, their advantages and disadvantages, applications, pricing, and more.

What is a CO2 Laser Marking Machine?

A CO2 laser marking machine is a cutting-edge piece of equipment that employs a carbon dioxide laser to permanently mark, engrave, or etch different materials. The CO2 laser functions in the infrared spectrum and emits a concentrated beam of light that interacts with the surface of the material.

As a result, the beam alters the material through vaporization, melting, or discoloration. The entire process is contactless so maximum precision and minimum damage to the material are guaranteed.

CO2 laser marking machines come with heightened versatility. They can mark on non-metals such as:

- Wood

- Leather

- Glass

- Plastics

- Ceramics

- Textiles

These machines are broadly used in industries such as manufacturing, packaging, and electronics. Their major applications include barcoding, product identification, and decorative designs.

CO2 laser marking machines are recognized for their high-speed operation, accuracy, and ability to produce detailed results. They are cost-effective devices for businesses that demand enduring and high-quality markings with no need for consumables like inks or dyes.

Advantages of CO2 Laser Marking Machines

CO2 laser marking machines come with a bunch of notable advantages. They are a favorable choice for the majority of industries that need meticulous and long-lasting markings. Let’s discuss what the main benefits of these machines are.

1. Wide Material Compatibility

One considerable benefit of CO2 laser marking machines is the fact that they can work with a broad spectrum of materials. Other laser marking technologies mainly focus on metals but CO2 lasers deliver their best performance at making non-metal materials like wood, leather, glass, ceramics, plastics, and textiles.

Such a high level of versatility is a critical feature for these machines. This is why CO2 laser marking machines are priceless devices for industries such as automotive, packaging, and consumer goods manufacturing.

2. High Precision and Accuracy

CO2 laser marking machines deliver absolutely meticulous and detailed markings. Therefore, they are ideal pieces of equipment for complex designs, logos, barcodes, and text.

Furthermore, these machines come with a non-contact essence in their process. This feature makes the user sure that the material will remain undamaged and come with outstanding clarity and precision.

3. Durable and Permanent Markings

The marks resulting from CO2 lasers are resistant to wear, chemicals, and environmental factors. This makes these machines flawless for applications that demand longevity. Regardless of why you use them—for branding, compliance labeling, traceability, and more—these machines provide readability and durability over time.

4. Cost-Effective Operation

CO2 laser marking machines will help you get rid of purchasing consumables like inks, dyes, or etching chemicals. This can result in a huge amount of cost savings.

What’s more, the negligible maintenance necessities and minimal downtime of these machines even boost their cost-effectiveness, hence all the long-term economic benefits.

5. Fast Processing Speed

The high-speed functionality of CO2 laser marking machines enables quick production cycles, resulting in boosted efficiency in manufacturing processes. They can handle large volumes of work without compromising quality, hence a suitable choice for high-demand industries.

6. Environmentally Friendly

CO2 laser marking is known as a clean and eco-friendly process. It doesn’t use hazardous chemicals or waste. The lowered need for consumables and energy-efficient operation of this process boosts its sustainability, which fits modern environmental standards.

7. Enhanced Automation and Integration

Modern CO2 laser marking machines can be effortlessly blended into automated production lines. They can easily match with computer-aided design (CAD) systems, which enables smooth operation and customization of marking patterns. As a result, productivity is sweetened and the risk of human error is minimized.

8. Versatility in Applications

CO2 laser marking machines support a broad variety of applications, including marking serial numbers on industrial components, creating artistic designs on consumer goods, and many more. Such a massive volume of versatility helps businesses meet different customer demands, maximizing their market competitiveness.

Disadvantages of CO2 Laser Marking Machines

CO2 laser marking machines come with a bunch of notable advantages; however, it doesn’t mean they have no drawbacks at all. Below, we are going to discuss some of their more important disadvantages you might need to know before acquiring one.

- Limited Metal Marking Capabilities: CO2 laser marking machines are mainly crafted for non-metal materials. Their performance on metals is limited. To enable them to mark metals with precision, you will need specialized treatments like coatings or additives. Obviously, this increases the final costs and intricacy of the project.

- High Initial Investment: The initial cost of purchasing a CO2 laser marking machine can be considerable. This is even more critical for businesses with limited budgets. The long-term cost savings from reduced consumables and maintenance may tangibly offset this notable expense. However, for smaller enterprises, this initial investment can be a big deterrence.

- Material Restrictions: Although CO2 lasers can work well with the majority of common materials, they might not be able to support certain ones such as reflective metals or transparent glass. That’s why additional adjustments—like coatings or pre-treatments—might be a must, which can make the process more complex.

- Maintenance Requirements: With gradually using these machines more and more, components such as the laser tube will need to be replaced. This increases your expenses because the component is pricey. Routine maintenance is a crucial task to make sure these machines can deliver their consistent performance. This will add to the total operational expenses, which can be a big obstacle for many.

- Heat-Related Damage: The high heat generated by the laser can sometimes even deform, scorch, or discolor the material. That’s more visible with delicate or heat-sensitive materials. That’s why careful calibration and expertise are critically needed to prevent damage to the materials.

- Complexity of Operation: Operating a CO2 laser marking machine usually requires you to be well-trained. You have to be able to optimize settings, ensure safety, and obtain favorable results. It is needless to say this will increase your training costs and decrease efficiency during the learning period.

Applications of CO2 Laser Marking Machine

CO2 laser marking machines are versatile devices that can be employed in diverse industries. That’s because they can create permanent and high-quality markings on different non-metal materials.

- Packaging Industry: CO2 laser marking machines are broadly used in this industry to mark barcodes, serial numbers, expiration dates, and QR codes on products. They are wonderful tools for materials such as cardboard, plastic, and glass as they deliver clear and enduring markings for traceability and compliance.

- Electronics Industry: CO2 lasers are used to engrave logos, circuit details, and component identifications on materials like plastic casings, circuit boards, and keypads. Since their process is precise and non-contact, they don’t damage delicate components.

- Consumer Goods: For branding and customization, CO2 laser machines engrave detailed designs, text, and logos on leather, wood, and textiles. They are vastly employed to produce promotional items, accessories, and personalized gifts.

- Automotive Industry: CO2 lasers mark labels, model numbers, and compliance information on automotive components. Their durable markings remain legible even in harsh environments.

- Medical Industry: In healthcare, CO2 lasers can be used to mark medical instruments. This helps in compliance with sterilization and traceability standards. Materials like plastics and ceramics are widely marked for identification.

- Art and Design: Creative artists use CO2 lasers to engrave distinctive patterns and textures on materials like wood and acrylic. This helps them deliver artistic and decorative products.

What Power CO2 Laser Marking Machine is Suitable for You?

To find out which power for a CO2 laser marking machine is good for you, you have to consider factors such as the materials and applications you intend to use it for. The table below shows the common powers of these machines categorized based on common applications and the materials they are proper for.

Power | Applications | Suitable Materials |

20–30W | Light-duty marking, barcodes, labels | Plastics, paper, thin textiles |

50–80W | Medium-duty marking, engraving, customization | Wood, leather, acrylic, thicker textiles |

100W and Above | Heavy-duty engraving, deep cuts, industrial use | Glass, ceramics, thick acrylic, and treated metals |

It is necessary to assess your certain demands such as speed, material thickness, and level of detail before you choose a proper power level. For the majority of cases, a mid-range (50–80W) CO2 laser machine is generally sufficient.

FAQs About CO2 Laser Marking Machine

Q: What materials can a CO2 laser marking machine work on?

A: These machines are powerful devices for marking non-metal materials such as wood, leather, acrylic, glass, ceramics, plastics, and textiles. If you tend to mark metals using these machines, you might need special coatings or pre-treatments.

Q: How does a CO2 laser marking machine work?

A: These machines benefit from a carbon dioxide laser beam to interact with the surface of a material. They use heat to alter the material’s appearance or structure. This way, these machines can craft permanent markings without physical contact.

Q: What industries benefit the most from CO2 laser marking machines?

A: Industries like packaging, electronics, automotive, consumer goods, and healthcare take advantage of these machines the most for their applications such as branding, barcoding, and compliance labeling.

Q: How long does a CO2 laser marking machine last?

A: The life cycle of a CO2 laser tube is typically between 10,000 and 20,000 hours, which hinges on how you use and maintain it. The primary maintenance cost is related to replacing this tube.

Q: Are CO2 laser marking machines environmentally friendly?

A: Yes, these machines are eco-friendly since they do not require inks, chemicals, or other consumables. As a result, they produce minimal waste and affect the environment negligibly.

CO2 Laser Marking Machine Price Range

The final price of CO2 laser marking machines hinges on diverse elements such as their power, features, and brand. However, their prices generally fall in three major intervals. The table below shows these price ranges along with the power of these machines and industries they are mostly used in.

Power | Industries | Price Range |

20–30W | Packaging, Textiles, Consumer Goods | $2,000–$5,000 |

50–80W | Electronics, Automotive, Branding | $5,000–$10,000 |

100W and Above | Industrial, Medical, Art and Design | $10,000–$20,000 or more |

High-end machines that are armed with modern features such as automation and customization capabilities can be offered at $20,000 or even more. That’s why you must consider your certain marking needs and preferred output quality before you purchase one of these machines, especially if you run a business with budget constraints.

Final Words

CO2 laser marking machines are known as indispensable devices for industries that demand efficient, unmistakable, and sustainable marking techniques. Since they can handle numerous types of materials and can integrate smoothly into production lines, they are a favorable choice for countless businesses worldwide.

Coping with initial costs and maintenance might be challenging; however, the long-term benefits of these machines—including cost savings, high-quality output, and environmental friendliness—certainly outweigh their drawbacks.

Regardless of the industry you work in—like manufacturing, healthcare, creative design, and more—investing in a CO2 laser marking machine can enormously sweeten productivity and competitiveness of your products.