Client Country: United States

Date: Jan 20, 2025

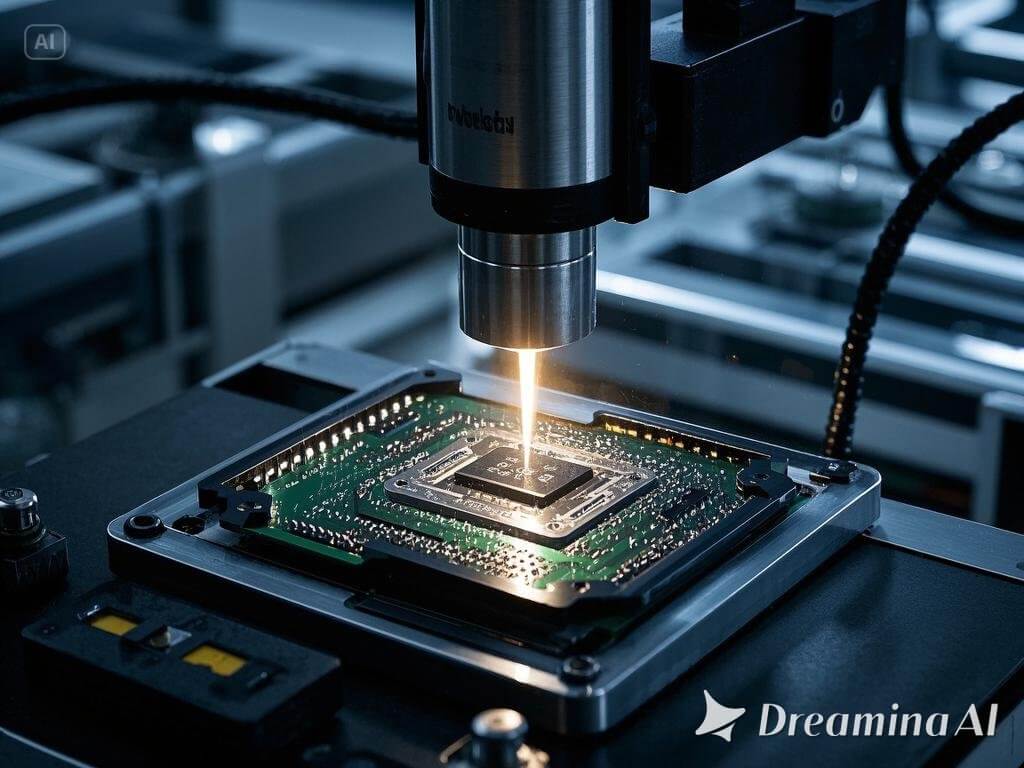

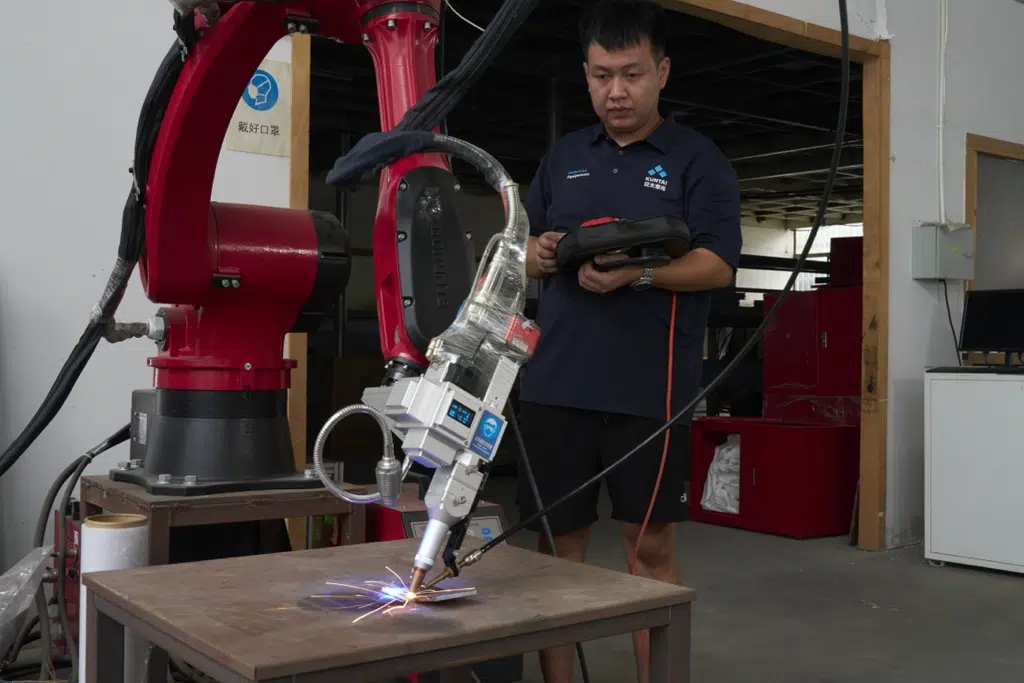

A customer from a prominent industrial manufacturing company in the United States visited our facility to evaluate laser marking systems suitable for producing metal nameplates used in heavy machinery. The company produces a variety of equipment, including industrial generators, and requires high-speed, high-precision marking solutions for serial numbers, logos, and safety labels. They aim to streamline production, reduce costs, and eliminate the inconsistencies found in traditional engraving methods. During the visit, the customer was particularly interested in our ability to mark on stainless steel and aluminum substrates, and discussed the integration of a laser marking system into their existing automated production line.

In addition to looking for cost savings, the customer emphasized the importance of durability and permanence in their markings. Given the harsh environments these machines often operate in, including exposure to oils, dust, and heat, the markings need to be resistant to wear and corrosion. Our laser marker provides the precision and reliability required to meet these needs. They were also impressed by the ease of integration with existing automation systems and the minimal maintenance required compared to other technologies. With a focus on reducing human error, the company plans to adopt this laser marking system in their assembly line for consistent output.