Table des matières

Why are portable laser marking machines becoming more and more popular?

Efficiency, mobility, and precision are key things in most industrial and creative apparatuses today, and this is where portable laser marking machines establish themselves as a mainstay. They are indeed revolutionizing the engraving, branding, traceability, and even customization processes for several materials, compact and easy to carry.

Be it manufacturing, automotive, electronics, or even arts, the market seems to be on a roll about ever-increasing flexible marking solutions. Due to this, portable laser machines have become highly popular.

Why could most professionals and small businesses prefer portable laser marking machines over traditional setups? This article tackles everything about portable laser marking machines, from versatility to affordability. Let us drill down into the benefits, categories, and pricing driving this global trend.

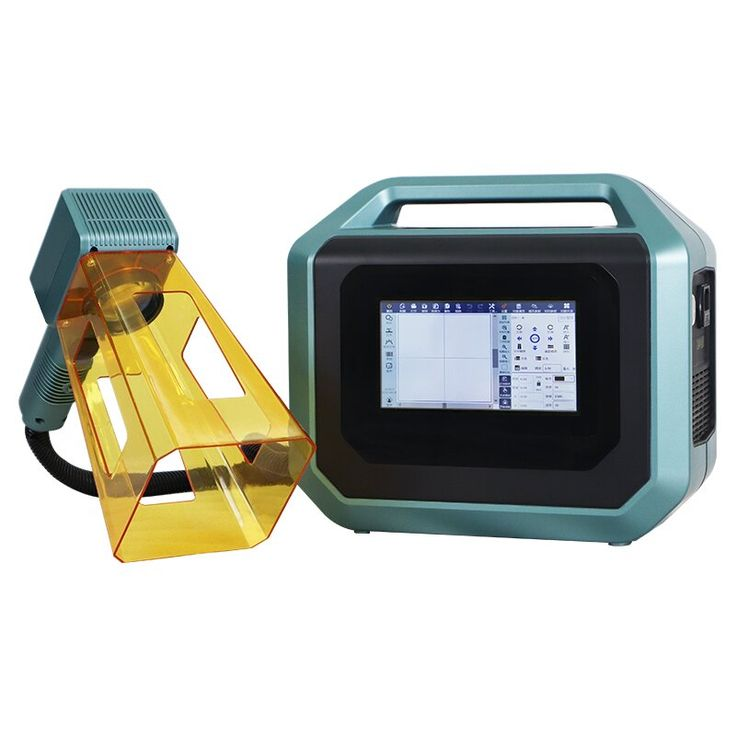

Part 1: What is a portable laser marking machine?

A portable laser marking machine is a compact and lightweight machine that marks, engraves, or etches marks on several valuable materials using concentrated beams. The main difference in portable machines as compared to stationary laser systems is in their mobility.

Portable machines can be easily taken to the object being marked; this is particularly important in the case of large, heavy, or fixed components. The machine types and laser systems chosen for the work will vary according to materials and an application’s unique requirements.

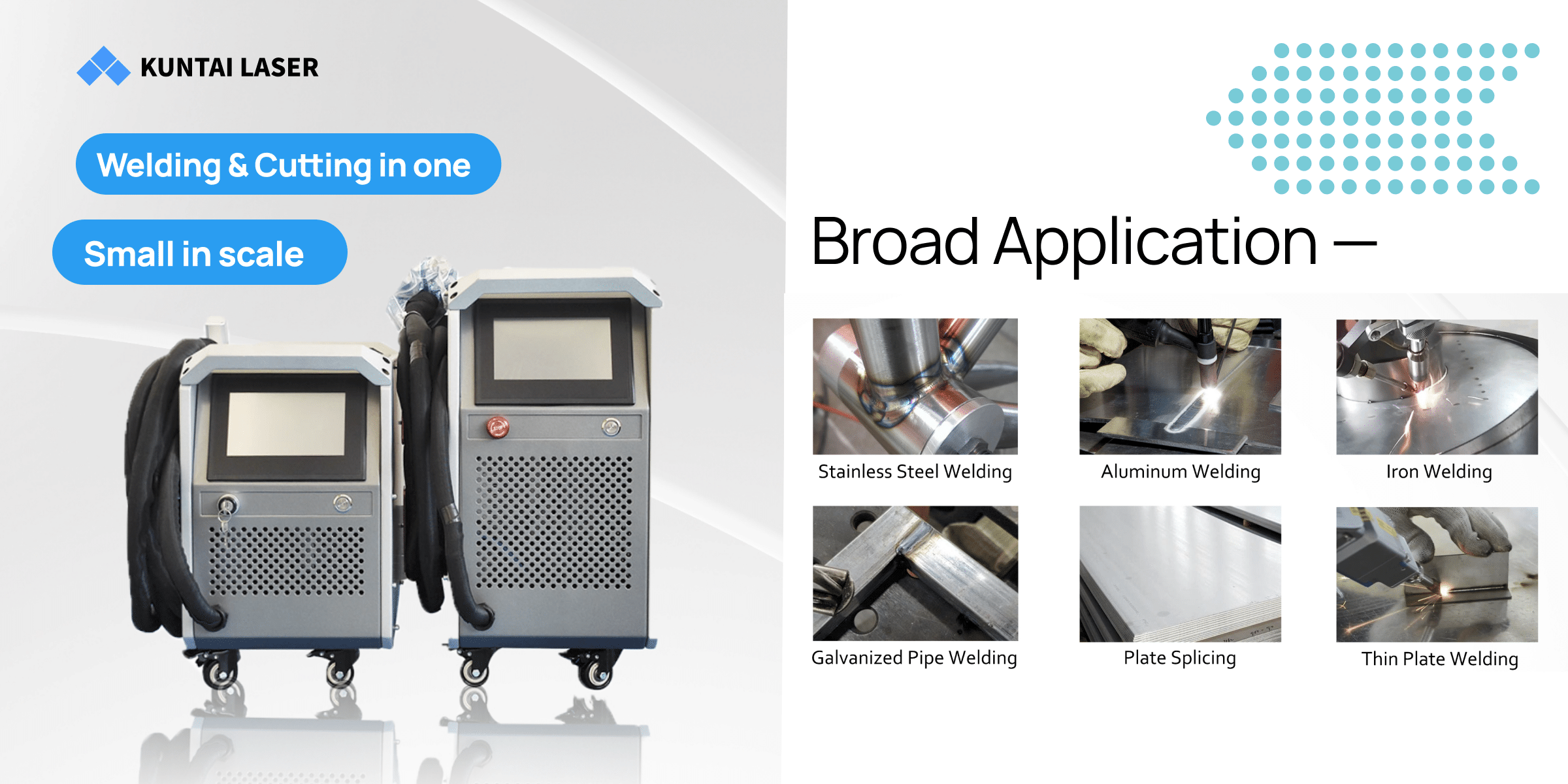

Part 2: What Are the Categories of Portable Laser Marking Machines?

Portable laser marking machines are classified according to their marking applications on materials, features, and types. The main differences between various laser marking types are as far to the source of the particular laser that is operated.

Here are the major classifications of portable laser marking machines:

1. The Fiber Laser Marked Machine

The fiber laser-marked machine is among the most widely used types in the present industry. It is characterized as a compact-sized fiber laser generator with excellent beam quality and high energy efficiency.

These machines are rugged, low-maintenance, fast, and very precise marking machines.

2. UV Laser Marking Machine

This is a type of laser machine that produces radiation at a 355nm wavelength. Short wavelengths enable fine laser beams that produce clean, accurate marks on sensitive surfaces.

One important aspect of UV laser processing is “cold processing,” because this type of laser barely transfers any heat to the material. This makes it even more attractive because it minimizes the risks of burning or distortion of sensitive materials.

UV laser markers are particularly effective for the very high accuracy on glass, ceramics, plastics, medical packaging, and electronic parts. Because of both their precision and minimal thermal effects, UV lasers are commonly the sources for applications where fine marking with no damage is paramount-comprising semiconductor, circuit board, and pharmaceutical facilities.

By large, UV marking machines offer small spot size and high absorption even by nonmetal materials, which makes them most preferred by firms needing ultra-clear permanent marks that would pose minimal intrusion into product structural integrity and that could be used to advantage by industries.

3. Laser Marking Semiconductor Machines

A semiconductor laser marking machine employs diode-pumped solid-state (DPSS) lasers previously being a widely used option for applications that could have alternatively chosen fiber lasers. They provide pretty good beam quality for the purpose and are equally well suited to marking metals, plastics, ceramics, and electronic components.

However, as fiber laser technology has advanced at an exponential rate, providing better performance, longer life, and lower maintenance-coupled with the benefits being offered by such laser technologies, the semiconductor laser marking machines are slowly being erased and replaced by fiber systems.

However, some industries are still utilizing such types of machines, especially for applications on already installed systems or certain wavelength concerns.

4. CO₂ Laser Marking Machine

CO2 Laser Marking Machine is are gas-based laser marking machine and is suitable for all kinds of nonmetals-from wood, leather, paper, glass, and plastic, through fabrics and acrylic to food packages.

Compared to inkjet or thermal transfer printing, CO2 laser markers produce a much more permanent effect, with high contrast and an even more beautiful result. They also eliminate the need for consumables-like ink or ribbon-for cost savings in the long run, as well as a lower environmental impact.

5. End-Pumped Laser Marking Machine

An end-pumped laser marking machine uses a solid-state laser pumped by a semiconductor laser as the light source. The laser beam is directed into the gain medium-typically, typically via optical fibers-which is most often some kind of crystal.

It produces a laser beam that is highly concentrated, of high quality, with superior power output. Such systems provide great precision and depth; they make it applicable for engraving deep marks on surfaces of metals, plastics, and ceramics.

They are especially useful with applications requiring fine detailing, high contrast, and excellent beam control, such as jewelry marking, microelectronics, and branding of luxury products. These machines are a little more powerful than fiber lasers and can engrave even more finely, which adds to their appeal for the most demanding industrial work.

6. Flying (On-the-Fly) Laser Marking Machine

The flying laser marking machine, also known as a tracking laser marking machine, is designed to integrate into the production line. Unlike traditional machines marking stationary objects, flying laser markers mark objects on the move and are thus suited for high-speed labeling on assembly lines.

These systems are often equipped with automation features such as real-time data input, serial number generation, and date coding that help companies maintain a distinct traceability without interrupting workflow. They are most frequently employed in food and beverage, pharmaceutical, cable and cosmetic packaging industries.

Flying laser marking machines work more productivity miracles and minimize downtime when used, especially in the high-volume production environment demanding non-stop operations and equal quality.

Part 3. What Are the Advantages of Portable Laser Marking Machines?

1. Great Mobility and Flexibility

Portability is perhaps the most obvious advantage of a laser marking machine. Instead of dragging heavy items to a stationary marking machine, portable marking units are generally brought to the workpiece.

For this reason, economical portable laser printing machines may be said to be especially beneficial for marking large, heavy, or fixed objects, difficult to move like machinery parts, pipes, or industrial components. These machines allow the freedom to mark anywhere, whether in a workshop, factory floor, or field, saving time and handling costs.

2. Compact and Space-saving Design

Portable laser markers are designed with space efficiency in mind. Their compact footprint makes them ideal for businesses that do not work in large spaces or have mobile operations.

There is no need for a huge establishment or special installation – either a small workbench or a place to use it handheld for some models will suffice. This is especially handy for those working from small workshops or jewelry, repair, and on-site service providers.

3. Multi-Material Applications

Even though they are small, portable laser marking machines can mark several materials. It may mark metals, plastics, ceramics, glass, wood, leather, rubber, and many more, depending on the laser source (fiber, UV, CO₂). Thus, it provides one-stop solutions for various problems in industries such as electronics, automotive, packaging, or gift customization.

4. Precision and Permanence of Laser Marking

Laser technology means precision, even with portable laser machines. These devices mark anything from crisp, clean barcodes or legible serial numbers to beautiful logos or fine graphic designs with lasting precision.

The non-contact nature of laser marking does not affect even the most delicate or complex surface. Laser markings also resist the multiline effects of abrasion, water, and chemicals. This is important for parts whose legibility must endure from cradle to grave.

5. Cheap Operation and Maintenance

Another significant benefit would be low-cost factors. The portable laser marking machines have hardly anything considered consumables. There are no inks, no chemicals, and no solvents needed. Hence, the continuous costs are greatly reduced compared to those incurred by inkjet or thermal methods.

In addition, the fiber and UV laser systems are low-maintenance with long service lives of usually more than 100,000 hours. With rare breakdowns and easy maintenance, their low maintenance requirements involve very few moving parts and air-cooled, grease-free rear systems.

6. Straightforward Operation and Software Integration

Most portable laser marking machines come with user-friendly software that supports different file formats and types of designs. They are mostly usable by technicians and sometimes novices, and perhaps, APs could take a small amount of training to operate.

Certain unit models include a touch screen, pre-loaded templates for easy marking, Wi-Fi, or USB options, making them user-friendly and efficient for quick-to-market applications.

7. Increased Efficiency

Portable laser marking machines deliver speed and high performance. With fast marking times and quick repositioning, operators can finish jobs with a faster turnaround than traditional systems.

For those companies that are engaged in on-demand engraving or batch marking, this means faster delivery and maximum productivity without any compromise on quality.

Part 4. What Materials Can Be Processed by Portable Laser Marking Machines?

A rundown of the materials usually processed by portable laser marking machines includes:

1. Métaux

Fiber laser marking machines are reserved primarily for all-metal marking with a broad range of industrial applications on marking:

- Stainless steel

- Aluminum

- Copper

- Brass

- Titanium

- Carbide

- Gold and silver

These machines can provide high-contrast, permanent markings such as serial numbers, barcodes, logos, and various patterns. A common application for this technology can be found in the automotive, aerospace, electronics, and jewelry industries for metal part identification and branding.

2. Plastiques

Both fiber and UV types of laser machines can mark plastics, however, UV lasers find better application on fragile heat-sensitive materials. Some common plastics include the following:

- ABS

- Polycarbonate

- Polypropylene (PP)

- Polyethylene (PE)

- Acrylique

UV lasers are characterized by non-contact and cold marking, which really helps eliminate any risks of burning and of deformation, particularly important in sectors that demand high precision, like medical device labeling or electronic component marking.

3. Glass and Ceramics

Glass and ceramics should be marked with UV and green lasers (emerald laser), due to marking schemes from the fine tests without crackings and damage to the material. Widely used for engraving decorations items, glassware labeling, and fine marking on ceramic tiles or insulators.

4. Wood and Leather

CO₂ laser marking is preferred for organic and non-metal materials, such as:

- Bois

- Cuir

- Paper

- MDF

Marking of these materials is a common practice in crafting, gift customization, packaging, and clothing industries, to place branding, intricate patterns, or logos with a natural and rustic appeal.

5. Rubber and Fabrics

CO₂ lasers can also mark rubber components, like seals and gaskets, and some textiles or synthetic fabrics for industrial applications and fashion.

Part 5. Price Range of Portable Laser Marking Machines

Below is a general price range table to help you understand what to expect when shopping for a machine:

Type de laser | Typical Power (W) | Matériaux appropriés | Price Range (USD) | Idéal pour |

Fiber Laser Marking Machine | 20W – 100W | Metals, hard plastics | $2,000 – $10,000+ | Industrial part marking, metal tools, jewelry |

CO₂ Laser Marking Machine | 30W – 60W | Wood, leather, glass, rubber, plastics | $2,500 – $8,000+ | Packaging, arts & crafts, leather branding |

UV Laser Marking Machine | 3W – 10W | Plastics, glass, ceramics, and delicate materials | $6,000 – $20,000+ | Medical devices, electronics, and high-precision work |

Semiconductor Laser Machine | 10W – 50W | Plastics, metals (limited), electronics | $3,000 – $8,000+ | Light industrial use, electronics, PCB marking |

End-Pumped Laser Machine | 10W – 30W | Metals, plastics, high-precision items | $7,000 – $15,000+ | High-precision industrial applications |

Green/Emerald Laser Machine | 5W – 10W | Glass, ceramics, sensitive plastics, and crystals | $10,000 – $25,000+ | High-end custom glass, crystal marking |

Flying/Navigation Laser Marker | Varies | Various, for high-speed production lines | $8,000 – $30,000+ | Mass production, automated labeling |

Conclusion

Portable laser marking machines have instantly changed the way businesses label, track their products. Whether one marks metal tools or customizes leather goods, or labels plastic components, there is a portable laser solution that fits the bill.

From entry-level to high-end, there is a laser marking machine for every business need at a budget suitable for that enterprise. With the innovative, tireless march of technology, the demand for these efficient and user-friendly investments will only continue to rise, solidifying their role in today’s production workflow.