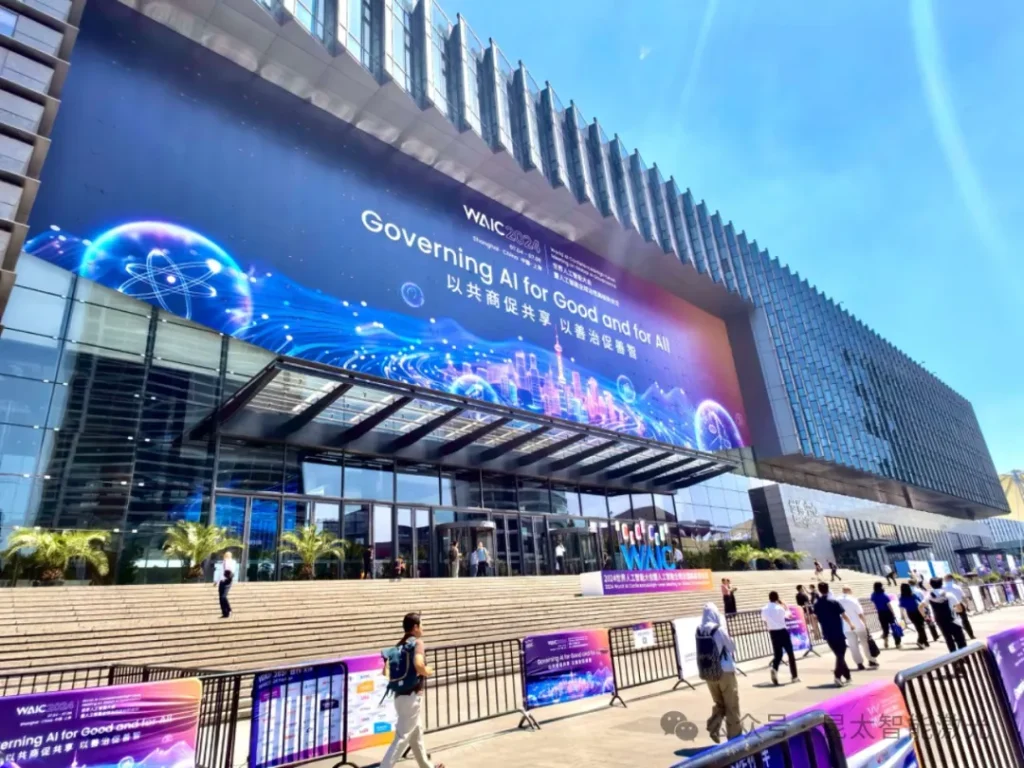

Kuntai Laser attended the 2024 World Artificial Intelligence Conference (WAIC) held at the Shanghai Expo Center. Our team gained a deep understanding of the latest AI technologies and their applications in various industries such as healthcare, finance, and manufacturing. This conference was not only a platform for learning and exchange but also highlighted how Kuntai Laser can integrate laser technology with AI to explore the potential synergies between the two, creating more possibilities for industrial applications.

At the exhibition, we encountered many companies developing AI humanoid robots. On their production lines for humanoid robots, Kuntai Laser’s laser engraving, marking, and cutting equipment can enhance the following processes:

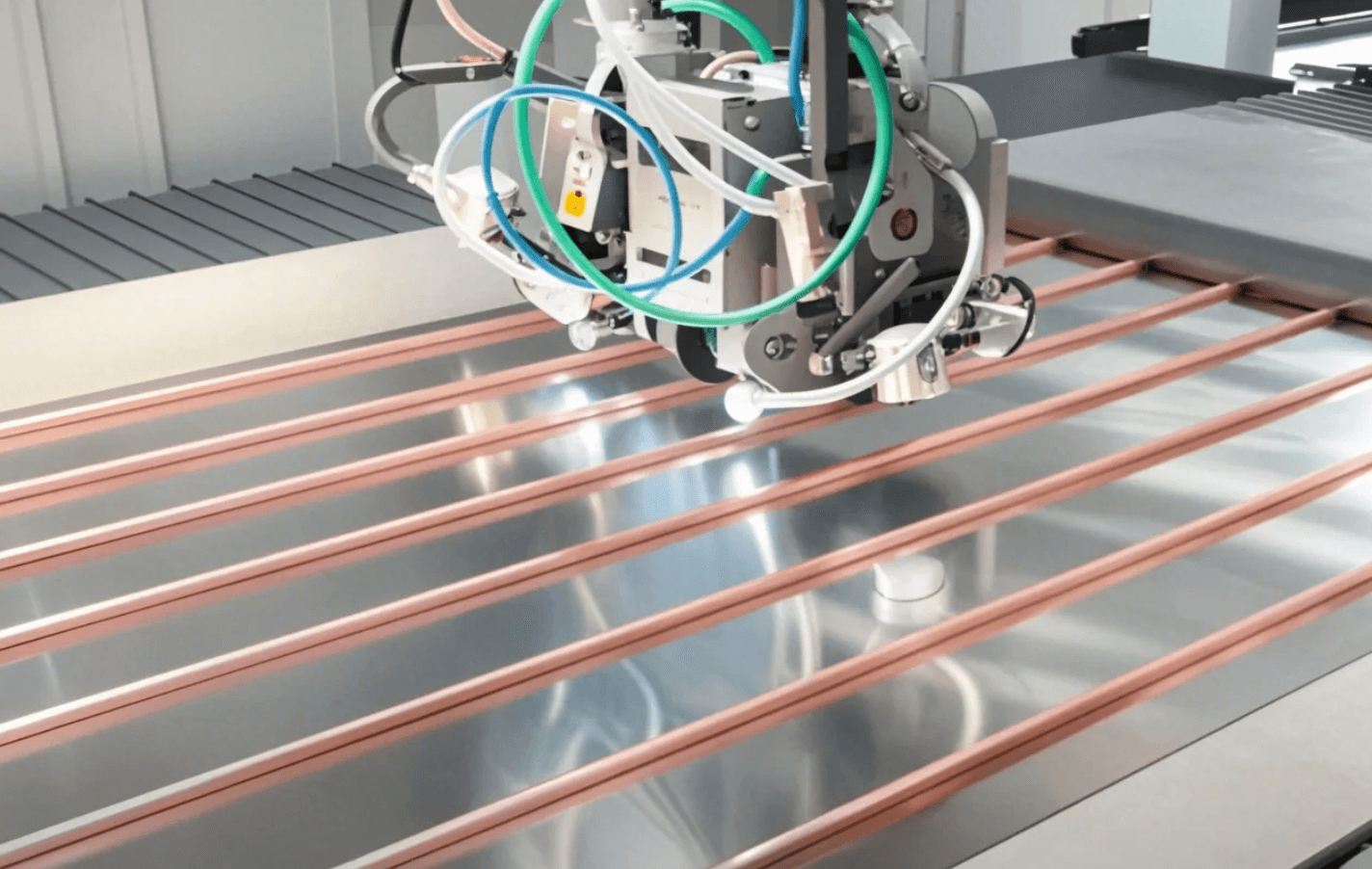

- Component Processing: Using laser cutting equipment to precisely cut materials for creating robot shells, frames, etc.

This year’s exhibition also featured several cutting-edge robotic arm development companies, demonstrating processes that are faster and more precise than human hands. Kuntai Laser also has many cases where computer vision and robotic arms are combined with laser marking, cutting, and engraving equipment, significantly improving efficiency and accuracy in industrial production lines. Computer vision uses cameras and algorithms to analyze and interpret images and videos. Robotic arms are robotic components capable of performing complex tasks, often controlled by precise motion control for tasks such as gripping, moving, and operating items. Kuntai Laser’s customized robotic arm laser systems have the following advantages:

-

- Visual Recognition: Computer vision identifies the position and orientation of workpieces, preparing them for subsequent processing.

-

- Data Transmission: Transmits the recognized information to the robotic arm and laser equipment, adjusting device parameters.

-

- Dynamic Adjustment: Computer vision monitors the processing process, making real-time adjustments to the laser equipment and robotic arm movements.

-

- Quality Inspection: After processing, the visual system checks and ensures the product quality.

-

- Automated Feedback: Uses collected data to optimize the production process and improve efficiency and quality through machine learning.

-

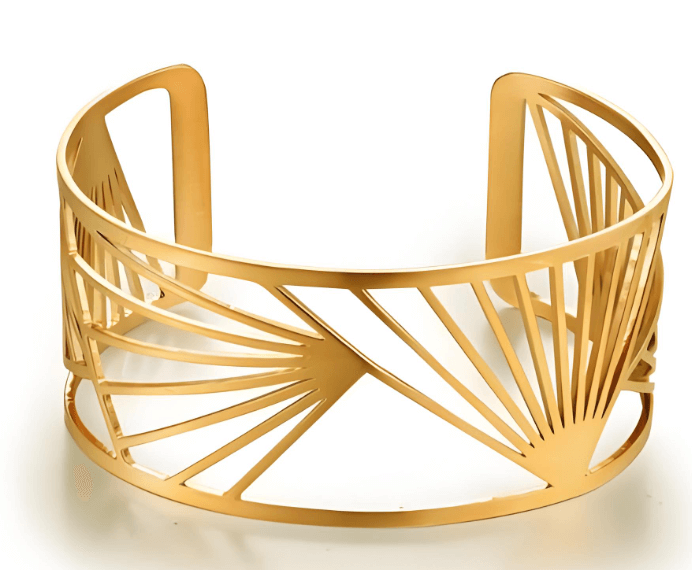

- Surface Treatment: Laser engraving is used to decorate or mark functional labels on the surface of components, such as serial numbers or functional identifiers.

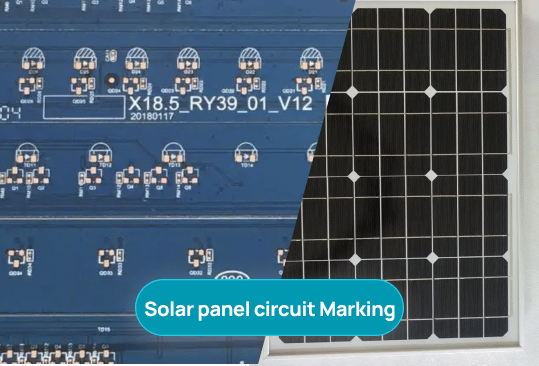

- Component Marking: Laser marking technology is used to mark models, production dates, and other information on circuit boards and other critical components for traceability and management.