Table of Contents

Pneumatic marking machines are known as game-changing devices in industrial engraving as they offer an enduring, efficient, and versatile approach to marking diverse materials. They are powered by compressed air and craft permanent indentations suitable for text, logos, serial numbers, barcodes, and many more.

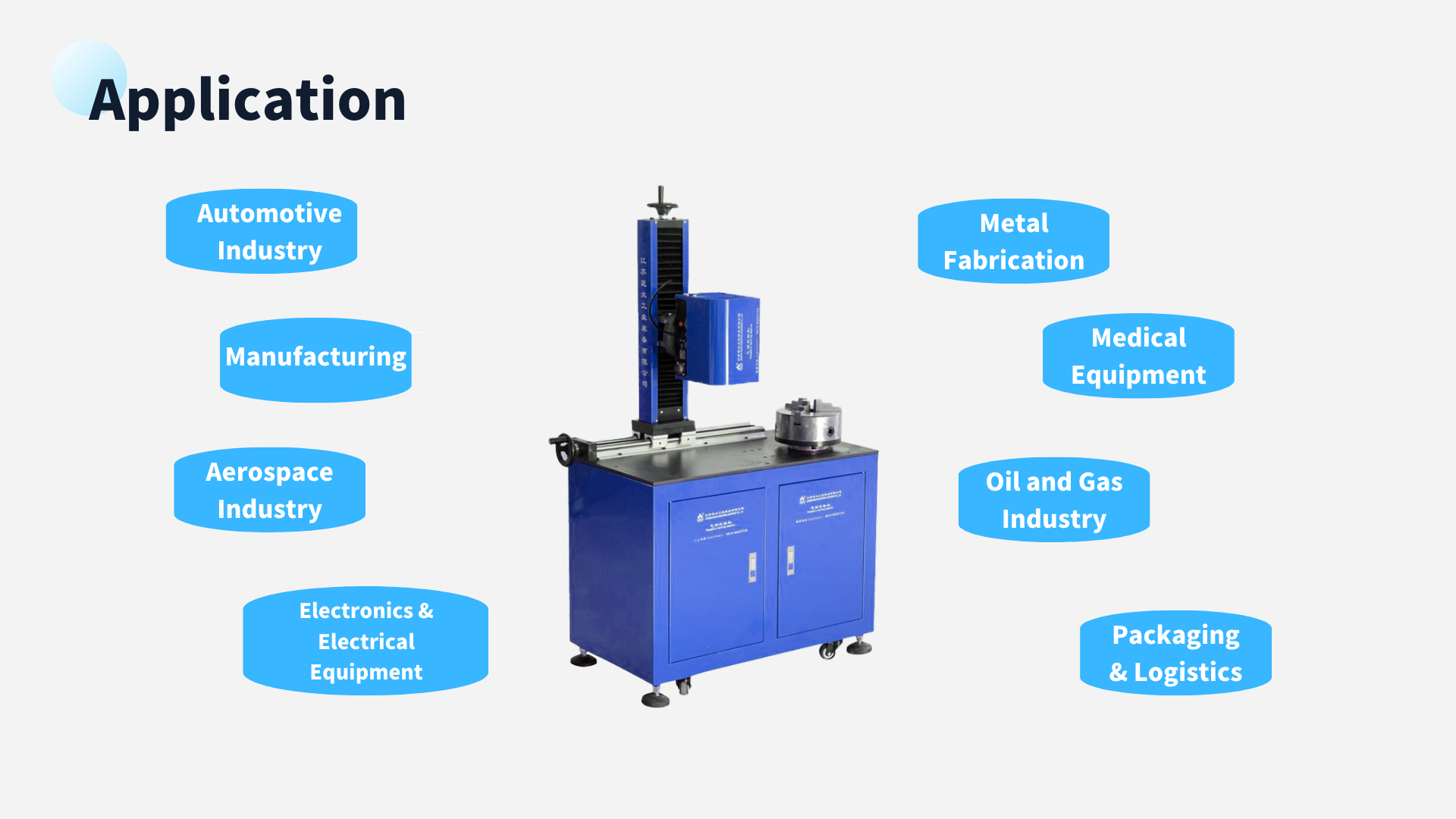

These machines are today widely used in multiple industries such as automotive, aerospace, and manufacturing because they deliver dependable traceability and compliance. Unlike laser or inkjet marking, pneumatic technology is recognized for its cost-effectiveness and powerful functionality, even in demanding environments.

Our comprehensive guide today aims to discuss all the advantages, disadvantages, applications, and fundamental considerations you need to know before choosing a pneumatic marking machine. Read on to find out everything about these wonderful machines.

What is a Pneumatic Marking Machine?

A pneumatic marking machine is an industrial machine that can permanently engrave/mark materials like metal, plastic, or wood. It uses compressed air to drive a marking pin or stylus and craft meticulous indentations on the material’s surface.

This process helps users create markings such as:

- Text

- Serial numbers

- Names

- Logos

- Custom designs

- Barcodes

- Graphics

- Date and time stamps

- Part numbers

- Batch numbers

- Custom patterns

These markings will remain legible even under harsh conditions. The machine’s functionality is based on dot-peen technology, where the stylus repeatedly hits the material to form the favorable design/text.

Pneumatic marking machines are broadly employed in industries like automotive, aerospace, manufacturing, and metalworking. That’s because of their elevated durability and trustworthiness. They can mark on flat, curved, or uneven surfaces, hence a versatile marking option for diverse applications.

These machines come with notable differences from other marking technologies such as laser and inkjet marking approaches. The table below compares these machines in brief.

Marking Technology | Durability | Precision | Cost | Speed | Suitable Materials |

Pneumatic | High | Medium | Moderate | Fast | Metals, Plastics, Wood |

Laser | High | High | High | Fast | Metals, Plastics |

Inkjet | Low | Medium | Low | Very Fast | Most Surfaces |

Advantages of Pneumatic Marking Machines

It is no surprise to see that pneumatic marking machines are indispensable components in industrial and manufacturing settings. They come with a bunch of notable advantages that make them highly valuable for different applications.

1. Durable and Permanent Markings

Pneumatic marking machines can deliver deep and permanent marks that resist harsh environmental conditions such as heat, moisture, and abrasion.

This high level of endurance helps markings stay legible over the product’s lifecycle. As a result, these marks will be ideal for parts that are subject to recurring use and wear.

2. High Versatility

These machines can be used for a broad spectrum of materials, including metals like steel, aluminum, brass, and nonmetals like plastic and wood.

What’s more, they can mark flat, cylindrical, or irregularly shaped surfaces. This allows these machines to be widely used for diverse applications across almost any industry.

3. Cost-Effective Operation

Pneumatic marking machines take advantage of compressed air as their primary power source. This helps them provide a low operational cost in comparison with other marking technologies like lasers.

This high level of endurance and also negligible maintenance demands sweeten the cost-effectiveness of these machines. This is even more tangible when using these machines in high-volume production environments.

4. Fast and Efficient Performance

Pneumatic marking machines work at high speeds. They can rapidly mark multiple parts in a short period. This high speed will not affect the elevated precision of the markings. Therefore, the high quality and efficiency of these machines are maintained in industrial processes.

5. Customizable Marking Capabilities

These machines can be effortlessly programmed to build customized markings such as serial numbers, QR codes, barcodes, logos, and alphanumeric characters. Such a high level of flexibility enables pneumatic marking machines to adapt to diverse identification and branding requirements.

6. Minimal Maintenance Requirements

Pneumatic marking machines are designed in a durable way so they can operate for a long time. Their moving components are fewer than mechanical systems. As a result, they demand negligible maintenance needs, which will significantly lower their downtime and associated costs.

7. Environmentally Friendly

Considering the fact that pneumatic marking machines do not depend on inks, solvents, or consumables, they are known as an environmentally friendly solution. Their operation is clean and does not yield hazardous waste. These factors make these machines appropriate for industries that value sustainability.

8. Improved Traceability

In industries like automotive and aerospace, traceability is of elevated importance. Pneumatic marking machines enable clear and permanent identification of parts, which simplifies tracking throughout the supply chain. Also, they guarantee compliance with regulatory standards.

9. Robust Design for Industrial Use

These machines are crafted to resist industrial environments as they are armed with sturdy components. These parts deliver steady performance even in demanding conditions. Their heightened resilience makes them dependable tools for heavy-duty applications.

10. Reduced Operator Fatigue

Automated features of these machines help them minimize their need for manual operators. This makes the marking process instantaneous and more ergonomic for operators. As a result, productivity soars and operator fatigue is minimized, especially in high-volume production settings.

Disadvantages of Pneumatic Marking Machines

Although pneumatic marking machines come with a plethora of advantages, you will regret it if you totally forget to consider their drawbacks before you purchase one.

- Noise Generation: Pneumatic marking machines are often noisy. That’s mainly because of the constant impact of the stylus on the material and the use of compressed air. This can exacerbate the current noise pollution in the workspace and may coerce operators into using hearing protection.

- Dependency on Compressed Air: These machines hinge on compressed air as their primary power source. In cases when the air supply system fails or when it is not efficient enough, this reliance can impact the machine’s performance and result in lengthy downtime.

- Limited Aesthetic Appeal: The markings produced by pneumatic machines are utilitarian. They may not meet aesthetic requirements for certain applications. Industries that demand highly detailed or visually adorable marks may eventually go with laser or other technologies.

- Surface Damage Risks: The impact-based marking process in these machines can lead to subtle damage or stress to thinner or delicate materials. For such applications, pneumatic marking machines might be inappropriate and limited.

- Lower Precision Compared to Laser Marking: Although pneumatic marking machines are known as accurate devices, they cannot obtain the ultra-fine precision and detail that is achievable with laser marking systems. This makes these machines less ideal for highly intricate designs.

- Higher Initial Cost: Although pneumatic marking machines are generally cost-effective in the long run, they have a higher initial investment in comparison with simpler alternatives such as hand engraving or stamping tools.

- Not Suitable for Non-Permanent Marking: Pneumatic machines are designed for permanent marks. This makes them inconvenient for applications that demand only temporary or removable markings.

- Maintenance of Air System: The compressed air system in these machines may need routine maintenance. This can easily increase operational responsibilities and costs when using these machines.

Applications of Pneumatic Marking Machines

Pneumatic marking machines come with diverse applications in different industries.

- Automotive Industry: These machines are broadly used in the automotive sector where they can mark engine parts, chassis numbers, and vehicle identification numbers (VINs). Their high endurance enables them to deliver clear identification throughout the product’s lifecycle.

- Aerospace Industry: In aerospace, parts need permanent and precise identification for traceability and compliance. Pneumatic machines mark serial numbers, lot numbers, and inspection codes on vital components like turbine blades and aircraft parts.

- Metal Fabrication: Metalworking industries use pneumatic marking machines to engrave logos, product IDs, and specifications on fabricated metal products. This helps them make sure their identification and branding are highly accurate.

- Manufacturing: These machines are widespread in manufacturing where they can mark tools, equipment, and machinery parts. These markings have a great role in streamlining inventory management and quality control processes.

- Electronics and Electrical Equipment: In electronics, pneumatic machines mark components like switches, panels, and casings. They guarantee traceability and compliance with safety standards.

- Oil and Gas Industry: Components like pipes, valves, and fittings in the oil and gas sector demand permanent markings to resist drastic conditions. Pneumatic machines deliver long-lasting and legible markings for such applications.

- Medical Equipment: In the medical industry, instruments and devices are marked with serial numbers, batch numbers, and regulatory information. Again, this is to ensure traceability and compliance with standards.

- Defense and Military Applications: Defense equipment and weaponry need to be marked permanently for correct identification in inventory tracking and accountability. Pneumatic marking machines are widely employed for enduring engravings in this sector.

- Jewelry and Artistic Marking: Although pneumatic marking machines are less widely used in this sector, they can engrave simple designs, serial numbers, or stamps on jewelry or small artistic items.

- Packaging and Logistics: These machines can also mark crates, containers, and packaging materials with tracking numbers or shipment details for accurate logistics.

FAQs About Pneumatic Marking Machines

Q: What materials can pneumatic marking machines engrave?

A: These machines are capable of engraving a broad spectrum of materials such as metals (steel, aluminum, brass, and titanium) and nonmetals (plastic, wood). Their impressive versatility for both hard and soft surfaces enables them to provide precise products for multiple industries.

Q: How do pneumatic marking machines work?

A: These machines take advantage of compressed air to drive a marking pin or stylus that hits the surface of the material. It creates repeated impacts that deliver permanent indentations in the form of text, numbers, logos, or codes.

Q: Are pneumatic marking machines suitable for curved surfaces?

A: Yes, these machines are engineered to work on flat, curved, or even surfaces with irregular shapes. They are armed with adjustable settings and stylus designs to accommodate such variations.

Q: What maintenance do pneumatic marking machines require?

A: These machines come with almost no crucial maintenance demands. You just have to make sure the compressed air system is clean and functional. Besides, the marking pin may need occasional replacement, which hinges on your usage pattern and material hardness.

Q: Can pneumatic marking machines be automated?

A: Yes, these machines can be integrated with automated systems—such as conveyors or robotic arms—for high-volume production lines. They also support programmable settings for custom-made and repeatable markings.

Q: What industries benefit the most from pneumatic marking machines?

A: Industries such as automotive, aerospace, manufacturing, metal fabrication, medical equipment, and oil and gas take the most advantage of pneumatic marking machines. These industries are in need of enduring and permanent markings for traceability, compliance, and branding purposes.

Pneumatic Marking Machines Price Range

The ultimate price of pneumatic marking machines hinges on several factors such as their features, size, and capabilities. If we categorize these machines into three main types, we can specify their price ranges as the table below shows.

Category | Price Range | Features |

Entry-Level Models | $1,000 – $3,000 | Basic manual operation, suitable for small businesses |

Mid-Range Industrial Models | $3,000 – $8,000 | Semi-automated, supports a variety of materials |

High-End Automated Systems | $8,000 – $20,000+ | Fully automated, programmable, and designed for large-scale production |

It is needless to say that purchasing a pneumatic marking machine that comes with more features and capabilities will force you to spend more. In this regard, high-end machines are generally used for industrial automation demands. For personal marking purposes, obtaining an entry-level machine would suffice.

Final Words

It is no surprise to see that pneumatic marking machines are today an indispensable component in almost any industry that demands permanent and trustworthy engravings. Their elevated endurance, efficiency, and versatility make them powerful marking devices for different applications in automotive, medical, and many other industries.

Although pneumatic marking machines come with some limitations—such as noise and reliance on compressed air—their cost-effectiveness and environmental friendliness are more notable than their drawbacks. It is integral to assess their features, applications, and price ranges before you pick the right machine that fits your needs.

Regardless of where you need one of these machines—whether for high-volume production or specialized marking—they can certainly deliver unparalleled value and guarantee elevated precision in their products.