Table of Contents

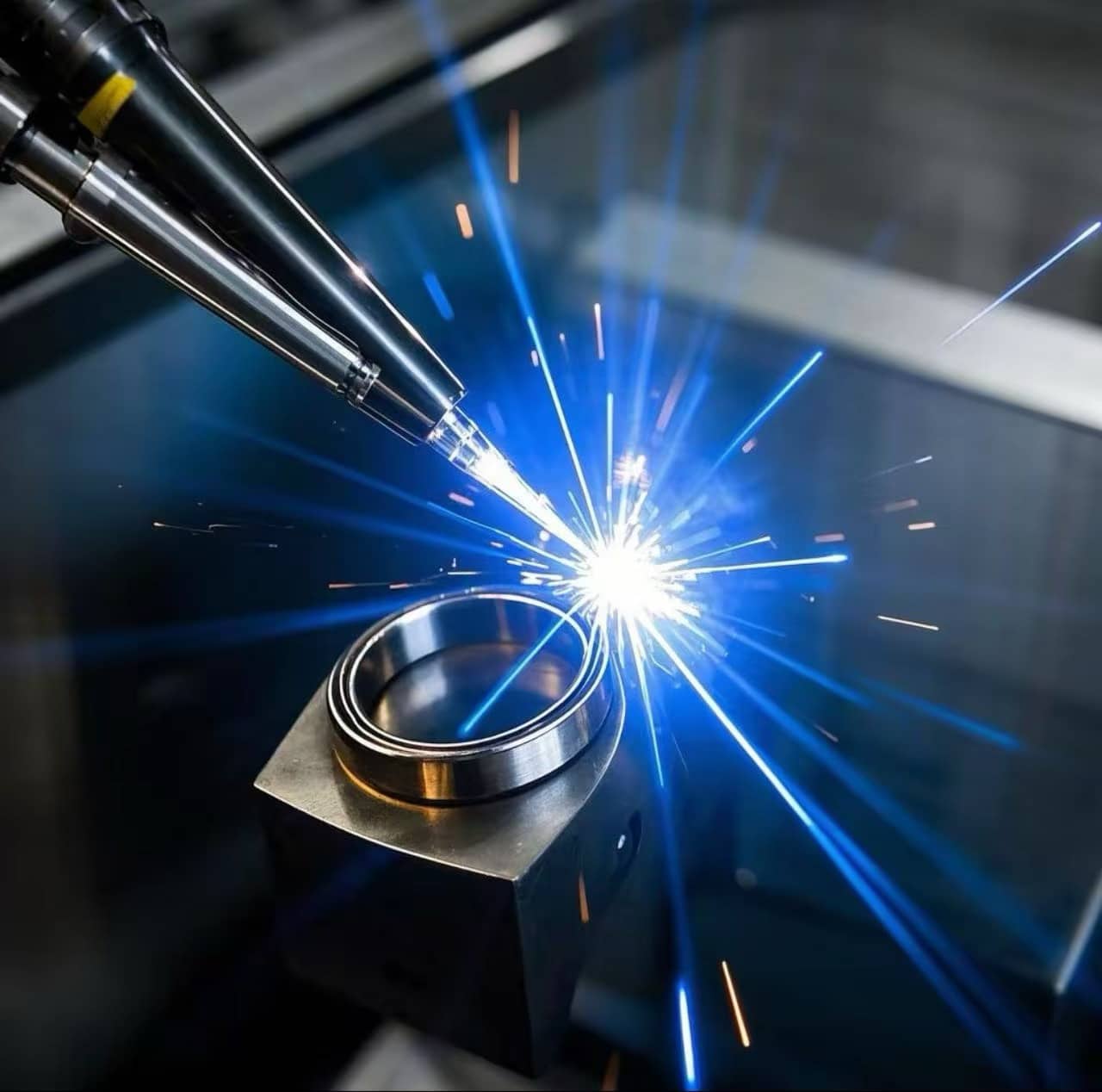

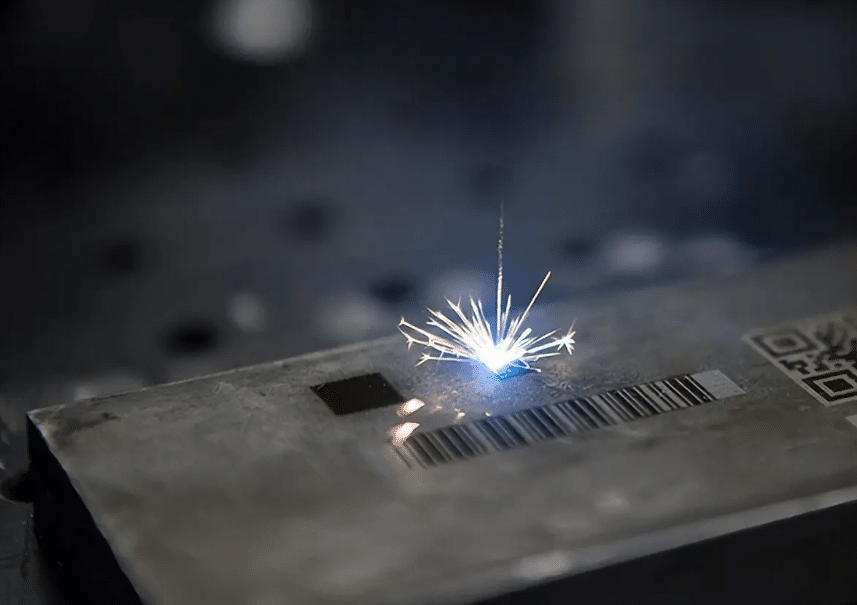

Laser cutters are recognized as revolutionary tools in a broad spectrum of industries as they deliver the utmost precision and efficiency in cutting and engraving diverse materials. These machines converge concentrated beams of light before they can vaporize or melt materials to craft the most delicate and intricate designs with almost no waste.

Precise laser cutters are employed for projects that demand clean, sharp edges of materials such as wood, metals, fabrics, and more. They are presented in different types so they can handle cutting needs for various materials.

In our post today, we intend to discuss a set of materials that laser cutters can or cannot cut. Also, we will discuss the applications and limitations of these machines for different materials.

What is a Laser Cutter?

A laser cutter is an absolutely precise tool that benefits from a concentrated beam of light to cut or engrave materials. The energy of the laser is accumulated into a thin line, which empowers the device to cut materials with the utmost precision.

These machines are praised for their versatility and are able to cut through multiple materials such as wood, plastic, metal, and fabrics. Laser cutters are known as a widely used tool in diverse industries such as:

Manufacturing and Engineering: Precision cutting of metals and materials in fabrication

Automotive: Cutting components like carbon fiber and sheet metal

Aerospace: High-precision cuts of lightweight materials like carbon composites

Electronics: Producing intricate circuits and components

Medical Devices: Crafting surgical tools and implant components

Signage and Advertising: Cutting acrylics and plastics for displays

Textiles and Fashion: Cutting fabrics and creating intricate patterns

Arts and Crafts: Engraving and detailed design work

The machine is engineered to direct a high-powered laser at the material before it can melt or vaporize the area of contact. Such a meticulous process empowers the machine to handle intricate designs, tight tolerances, and negligible waste.

You may find diverse types of laser cutters on the market, including CO2, fiber, and crystal lasers. Each of these machines works for certain types of materials in different applications.

Laser Type | Best For | Limitations |

CO2 Laser | Wood, Acrylic, Leather, Fabric | Not effective on metals |

Fiber Laser | Metal, Plastics | Not ideal for organic materials |

Crystal Laser | Fine Engraving, Glass | Expensive, shorter lifespan |

In essence, laser cutting is favored for its ability to craft clean edges, diminish manual labor, and give birth to detailed patterns with almost no endeavors.

Can You Cut Acrylic with a Laser Cutter?

Yes, you can cut acrylic with a laser cutter. As a matter of fact, acrylic is recognized as one of the most friendly materials for laser cutters because of its clean-cutting properties.

A CO2 laser cutter is widely employed to cut acrylic in a breeze because it can meticulously cut through multiple thicknesses of acrylic. In this cutting process, the laser beam is focused on the acrylic sheet and melts/vaporizes the material along the predefined path.

Laser cutting of acrylic provides you with smooth and polished edges. There is no need for additional sanding or finishing. This empowers the machine to deliver complicated designs, which makes it an ideal option for applications like signage, display stands, and art pieces.

Acrylic is offered in diverse varieties, including cast and extruded. The former delivers outstanding results for laser cutting. The thickness of the acrylic helps you understand the laser’s power and speed settings so you can enjoy an optimal cut.

Despite all these, some precautions are worth mentioning. Since cutting acrylic releases fumes, ventilation is of heightened importance. Also, you have to avoid overheating the material, which may result in warping or discoloration. The correct settings and accurate attention to detail allow the laser cutting of acrylic to deliver professional-grade results.

Can a Laser Cutter Cut Glass?

Yes, a laser cutter can cut glass. However, the process is somewhat more challenging than cutting materials like wood or acrylic. In the case of traditional glass, cutting with lasers isn’t that widespread, which is because of the reflective nature and brittleness of glass.

However, specialized laser cutters—like those armed with a CO2 laser—can engrave or score glass surfaces with precision. The interesting point here is that the laser beam doesn’t entirely cut through the glass; instead, it just weakens the glass surface, which makes it effortless to snap along the preferred line after scoring.

To prevent shattering or cracking of the glass, laser cutters are employed at lower power settings and slow speeds. The process usually gives birth to frosted or etched patterns on the surface, hence the higher popularity of laser engraving compared to cutting.

Applications of laser cutting for glass include creating decorative glassware, engraving mirrors, or producing customized glass signs. Still, limitations worth noting include the need for precise calibration and the possibility of stress fractures due to thermal shock.

In cases where manufacturers need clean cuts, they typically use water-assisted laser cutting. It cools the glass down during the process. Despite all the challenges, laser cutting is an effective technique for the glass if the right equipment is applied.

Can a Laser Cutter Cut Carbon Fiber?

Yes, a laser cutter can cut carbon fiber. Still, there are critical considerations. Before anything, you should know that carbon fiber composites are crafted from fibers bonded together by a resin, and the resin may behave entirely differently under laser cutting.

If your laser cutter type is CO2, the carbon fibers themselves cut cleanly; however, the resin can generate hazardous fumes as it burns. That said, it’s integral to provide appropriate ventilation or an exhaust system that can safely extract such toxic fumes.

Laser cutting for carbon fiber is effective for thin sheets—generally up to roughly 5 mm in thickness. However, it may not be similarly effective for thicker carbon fiber sheets, which is because of the difficulty of penetrating through the resin layers.

It is worth mentioning that some laser cutters are not designed to handle the material’s reflective properties. Therefore, checking the machine’s specifications is of great importance. Plus, since the process may leave rough or frayed edges on the carbon fiber surface, additional post-processing—like sanding or coating—might be necessary.

Laser cutters deliver precise cuts on carbon fiber, which makes them suitable for complex designs and prototypes used in industries such as aerospace, automotive, and sports equipment. Despite all the challenges in using them, laser cutters are an effective tool for cutting carbon fiber.

Can a Laser Cutter Cut Vinyl?

No, cutting vinyl with a laser cutter is not recommended. Vinyl mostly comes in the form of PVC, or polyvinyl chloride. It comprises chlorine, which is prone to becoming hazardous when exposed to the heat coming from a laser.

When you cut/engrave vinyl with a laser cutter, it can release chlorine gas. Not only is chlorine harmful to the operator but it can even damage the laser cutter’s components—especially the optics and metal parts—through corrosion. Consequently, the life cycle of the machine is shortened and the working environment becomes hazardous.

Vinyl is broadly employed in sign-making, adhesive decals, and other applications. Still, alternative cutting methods are considered safer and more appropriate for vinyl than laser cutting, including blade cutters or CNC machines. Blade cutters can handle vinyl with ease, without generating harmful fumes or damaging equipment.

If you insist on laser-cutting a material that resembles vinyl, you better opt for laser-safe alternatives—such as polyester-based films—which can be cut with no toxic emissions. If your project includes vinyl materials, don’t forget to check the material’s safety guidelines and the manufacturer’s recommendations for your laser cutter.

Can a Laser Cutter Cut Wood?

Yes, a laser cutter can cut wood. In fact, wood is widely cut with this cutting technology. Wooden materials respond to laser cutting appropriately because they vaporize cleanly and enable precise cuts and complex structures.

You can use laser cutting to cut different types of wood, including:

– Plywood

-Hardwood

-Softwood

-MDF (Medium-Density Fiberboard)

Each of these wood types demands different laser power settings, which hinge on its thickness and density. Among them, CO2 lasers are broadly used to cut wood as they deliver smooth edges.

Laser cutting is a cutting-edge technique to craft custom furniture, decorations, and engraved items. Also, it’s popular in arts and crafts. Its capability to create highly detailed patterns makes it a top choice for both designers and hobbyists.

Still, it must be mentioned that some woods—particularly those with high amounts of resin and oil content—may burn easily and produce a lot of smoke, resulting in charred edges or darkened areas around the cut. That’s why appropriate ventilation is integral to prevent the accumulation of smoke.

Can You Cut Cardboard with a Laser Cutter?

Yes, a laser cutter can cut cardboard. As a matter of fact, cardboard is an excellent material for laser cutters because it is lightweight and easy to work with, thereby enabling clean cuts.

Cardboard is commonly used in packaging, prototyping, and model-making because of its affordability and availability. Using a laser cutter for cardboard enables complicated designs, meticulous cuts, and detailed engravings. These are often tough to achieve with conventional cutting tools.

CO2 laser cutters are widely used for this purpose. They can handle cardboard with different thicknesses. You just need to modify the power and speed settings based on the material’s thickness to achieve smooth cuts and avoid burning or charring the edges. Thicker and corrugated cardboard may generally demand more power and slower cutting speeds.

Laser-cutting cardboard helps you craft customized designs for packaging or mockups without the need for dies or molds. However, safety is paramount because of the flammable essence of the material. Proper ventilation and monitoring are critical in avoiding fire risk, particularly when you work with high-powered laser settings.

Can You Cut Leather with a Laser Cutter?

Yes, you can cut leather with a laser cutter. Laser cutting is a widespread option for creating custom leather goods such as wallets, belts, shoes, and even elaborate designs for art projects.

CO2 laser cutters are widely employed to cut/engrave leather because of their precision and ability to craft delicate patterns with no physical tools. The laser vaporizes the leather along the path of the beam, delivering clean and accurate cuts and sharp details.

Leather thickness directly affects the power settings and cutting speed. Thicker leather demands more power and slower cutting speeds, which is the opposite of settings for thinner leather. The process also enables customized engraving to craft logos, text, or intricate designs on the leather surface.

The leather type is also of great importance. Natural leather cuts easily, but synthetic leather may comprise hazardous chemicals that can release toxic fumes when in contact with a laser. Here again, the importance of adequate ventilation cannot be stressed more.

Which Materials Can Be Cut with a Laser Cutter?

Laser cutters can be employed to cut diverse materials, hence their unquestionable popularity in multiple industries. More common materials in this case are wood, acrylic, fabric, and paper.

Still, metals like stainless steel and aluminum can also be cut with higher-power lasers. Plus, plastics such as acrylic and polycarbonate can be cut took, though they demand certain settings to avoid melting.

The table below shows materials that can be cut with a laser cutter along with necessary notes.

Material | Laser Cuttable | Important Notes |

Wood | Yes | Ideal for clean cuts, minimal charring |

Acrylic | Yes | Produces polished edges |

Fabric | Yes | Suitable for intricate patterns |

Paper/Cardboard | Yes | Easy to cut with low power |

Metals (Thin sheets) | Yes | Requires higher-power lasers (fiber/CO2) |

Leather | Yes | Can be natural or synthetic (ventilation required) |

Which Materials Cannot Be Cut with a Laser Cutter?

The primary reason why certain materials are not safe to cut with laser cutters is their potential for releasing harmful fumes or damaging the equipment. Materials like PVC and polycarbonate release toxic chemicals if cut with laser cutters. Also, metals such as copper and brass are difficult for standard CO2 lasers due to their reflective properties.

The table below shows materials that cannot be cut with a laser cutter along with reasons for that.

Material | Laser Cuttable | Reasons |

PVC (Vinyl) | No | Releases harmful chlorine gas |

Polycarbonate | No | Melts and produces toxic fumes |

Copper/Brass | No | Reflective surfaces damage laser components |

Fiberglass | No | Contains epoxy resins that produce harmful fumes |

Styrofoam | No | Melts easily and produces toxic emissions |

Final Words

Laser cutters are powerful tools capable of cutting through a broad collection of materials, including wood, acrylic, metals, fabric, and more. Still, you must understand the material’s specifications beforehand so you can guarantee the safety and optimal performance of the machine.

Although some materials such as leather and cardboard are easily cut with laser cutters, some others like PVC or polycarbonate might be hazardous due to their toxic fumes emissions. The key point here is to pick the right materials and settings so your machine can generate precise results in any industry.